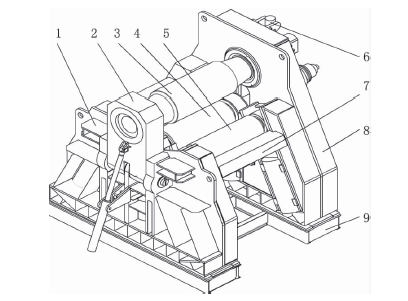

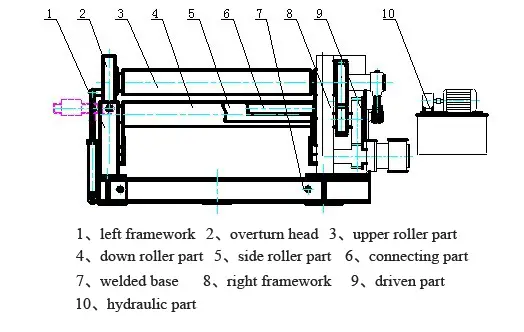

This paper presents the design result for the development of a motorized sheet metal rolling machine. The two lower roll can move up and down in arc way around fixed roller.

Load Analysis And Driven Power Calculation 4 Roll Bending Machine Machinemfg

Johnson Design of machine elements Tata mc-Graw Hill.

. They can prevent skidding while rolling thin. It can finish pre-bending and rolling by feeding once. Therefore the calculation of the force analysis and driving power of the plate rolling machine is very important to the design of the roll bending machine.

Of Mechanical Engineering AbhaGaikawadPatil Engineering College Nagpur Maharashtra India Abstract-Metal forming can be defined as a process in which the desired size and shapes are obtained through plastic deformation of a material. Four roll machines do not require the operator to remove flip and then try to square and reposition the plate a second time after pre-bending as is the case with three roll IP machines. μ friction coefficient.

Johnson The bending of plate using a three roll pyramid type plate bending machine J. The research aims at making it possible to do the operations on a single machine. These two methods are combined in one single machine to work smoothly and efficiently.

DesignPlate Rolling Machine Calculation neko2d org September 23rd 2018 - DOWNLOAD PLATE ROLLING MACHINE CALCULATION plate rolling machine calculation pdf Here is the steel weight 33 44. Modern rolling machines are usually cambered crowned at 50 of the full-rated value of the machine. Design and Fabrication of a Three - Rolls Plate Bending Machine Patrick Ejebheare Amiolemhen Joseph Konas Abiegbe Department of Production Engineering Faculty of Engineering University of Benin PMB 1154 Benin City Nigeria Abstract This paper is aimed at designing and fabricating a low cost motorized 3-rolls plate bending machine to bend a.

Calculation formula including steel plate tube bar round square flat hexagonal3 roll bending machine variable. The motor power can be calculated according to the following formula. Rolling machine for small scale manufacturers IJERT VOL1 May2013.

DESIGN CALCULATIONS The whole machine elements are designed using books Design of machine elements by author VB Bhandari and PS Gill Design data book 21 Selection of Pipe. Automatic controls use an encoder to track movement of the plate through the machine. All machines are really designed to function best when used to half their working.

Design Development of Three Roller Sheet Bending Machine Mahesh Gadekar1 Mr. Therefore a 1-inch machine is cambered to roll 12-inch plate. The plate is kept square without slipping during both pre-bending and rolling because of the constant secure clamping of the top and bottom rolls.

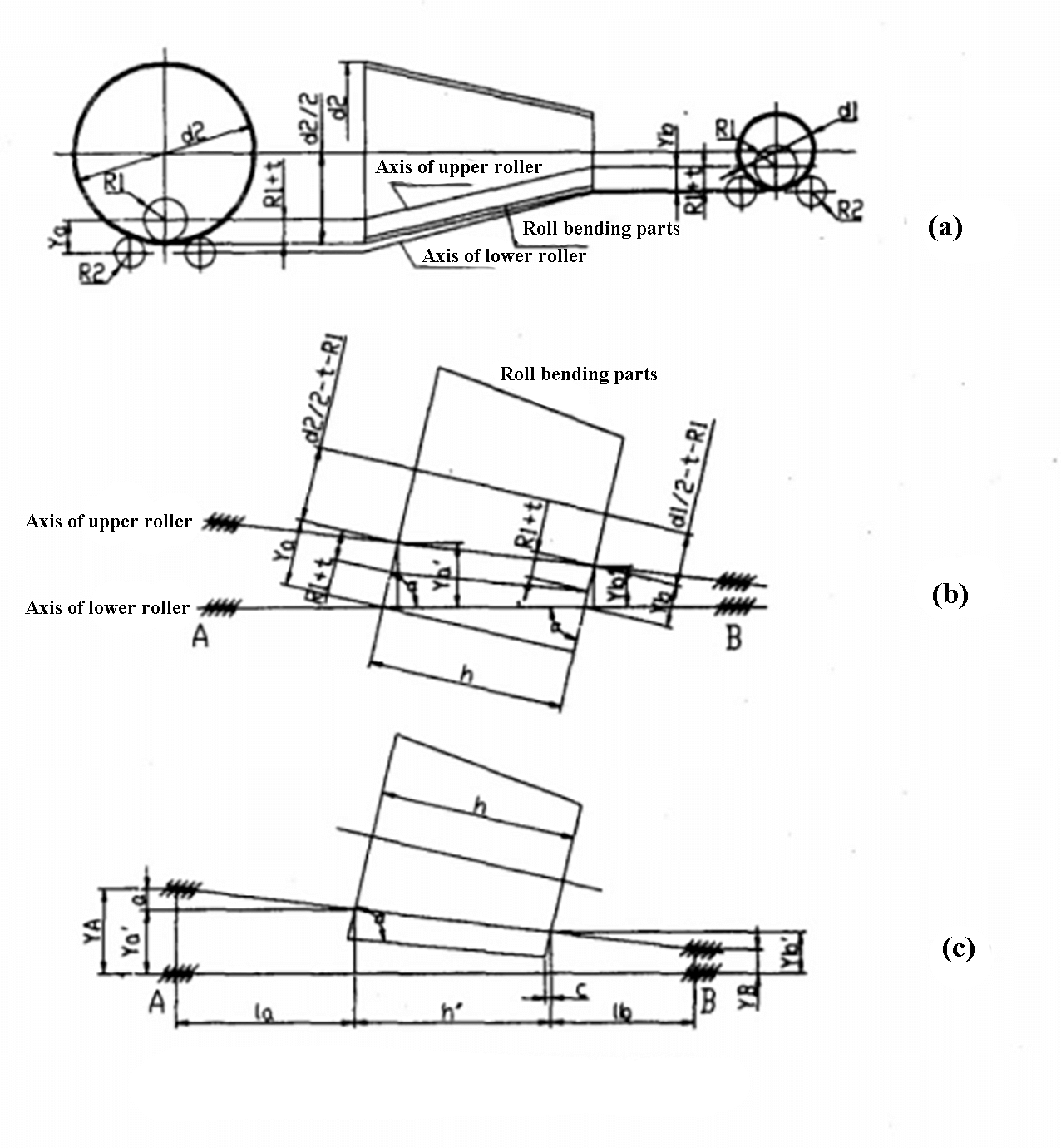

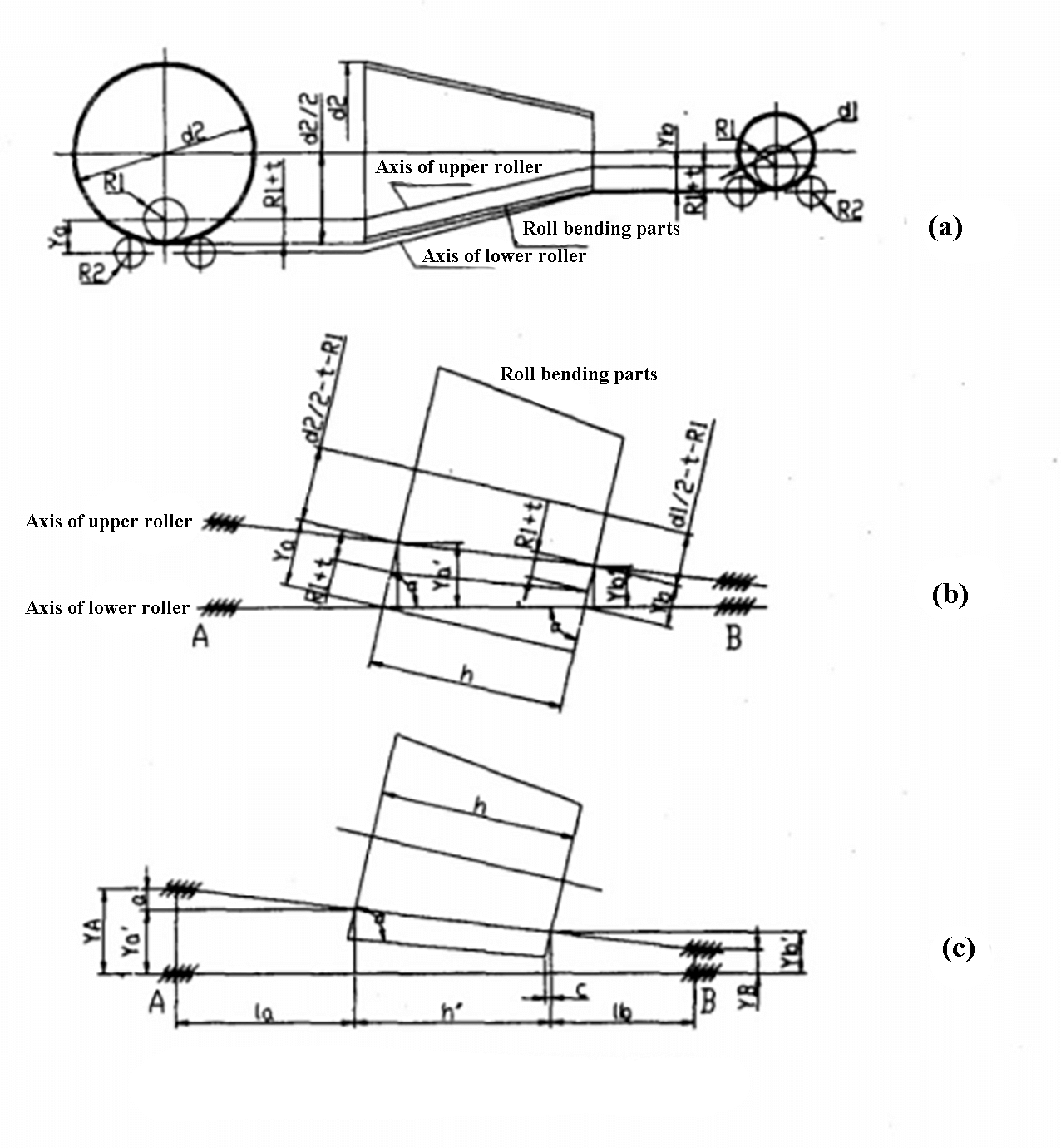

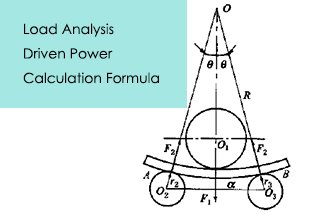

D rolling friction coefficient of roller and steel plate the steel plate is 00008 m. The mild steel plate Properties are 2 Youngs Modulus E207GN m Elastic limit yield stress σ y 515MN m 2 Poissons ratio034 Given data from the specification of the machine 22 The plate thickness t1mm Upper roller diameter du50mm Lower roller diameter dl50mm Lower rolls centre distance 2f120mm Theplate rolling speed v 55ms. In this post the calculation of the force capabilities of symmetrical three-roll bending machine is one of the methods the other types of plate rolling machine can take it for reference.

P the total pressure acting on the roller kN. CALCULATIONS OF COMPONENTS 31 Design of Spur Gear Material EN8 hardened and tempered S ut 550nmm2. The aim of the research is to design a rolling machine that can roll metal sheets of up to 3 mm thickness.

A Project Report On DESIGN AND FABRICATION OF SHEET METAL ROLLING MACHINE Submitted By HARSHDEEP SINGH INAYATULLAH FAROOQUI Under the guidance of Prof. Plate Rolling Machine Calculation The calculation of the main driven power of the plate roll bending machine is the key reference data for. Operating Parameters of the Machine Begin with selecting the correct machine to roll the part on.

The rolling is carried out in a modern and very powerful four-high mill from 1997 shown in Figure 4. Features of Three Roller Rolling Machine. A Plate Rolling Machine is a machine that will roll different kinds of metal sheet into a round or conical shape and a rod bending machine will roll or bend different kinds of metal sheet into right angles or circular shapes.

The slab thickness is normally 220 mm but also 290 and 140 mm exist. Calculation of motor driving power of plate rolling machine. The lower roller of the plate of plate rolling machine is the 2653 1 For thickness F 2 T R neutral layers radius of the rolling in mm R 05 d min R 05388 194 mm F 2 F 2 11563 N According to the force balance the pressure force F 1 which is generated by the upper roller acting on the rolling plate ie 2F 2 F 1.

This paper presents the design construction and evaluation of a sheet metal rolling machine for small-scale enterprises. All the material is reheated before rolling up to 1160-1245C. The three rollers are driving rollers.

The two ends of controlled by PLC. The flowchart of heavy plate production in Oxelösund. Although there are many.

A rigid forming roller a free. DESIGN AND ANALYSIS OF MS ROLLER IN SHEET METAL ROLLING MACHINE Vaibhav Bankar Pramod Vishwakarma. Sheet metal rolling is a process of converting a sheet of metal into a complete hollow cylinder.

Download Plate Rolling Machine Calculation free to listen on your mobile device iPODs computers and can be even burnt into a CD. The machine consists of three rollers. M k bending torque kNm.

Four-roll plate rolls generally are the only equipment with NCs or CNCs because the fourth roll provides constant pinching action minimizing the chance for slippage. Semester VIII MECHANICAL 2013 - 2014 from Rizvi College of Engineering New Rizvi Educational. If the plate slips the bending roll movements will be out of synch with the rolling movement.

The upper roll on 3-roll plate bending machine is fixed. The present innovation relates to the plate bending machine which operates with rollers. The collections also include classic literature and books that are obsolete.

Vishwakarma Submitted as a partial fulfillment of Bachelor of Engineering BE. The weight of the plates is between 16 and 133 tons. Bending method for rolling operation.

Plate Rolling - Capacity Calculator - Table showing maximum cylinder length we can roll for given diameter and wall thickness. Amol 2 Student1 AsstProf2 Dept.

Basic Guide To Roll Bending And Plate Roll Capacity Conversion Machinemfg

Pdf Development And Evaluation Of Metal Rolling Machine For Small Scale Manufacturers

Load Analysis And Driven Power Calculation 4 Roll Bending Machine Machinemfg

Load Analysis And Driven Power Calculation Symmetrical 3 Roll Plate Bending Machine Machinemfg

Pdf Design And Fabrication Of Sheet Rolling Machine A Project Report Vino The Great Academia Edu

Pdf Development And Evaluation Of Metal Rolling Machine For Small Scale Manufacturers

Operation Manual Of W12 Four Roller Plate Bending Machine Machinemfg

0 comments

Post a Comment